FluiDimensions

FluiDimensions is a Engineering Design and Consulting company with its principle office in Pune, Maharashtra, India. FluiDimensions believes in solving industrial problems by working very closely with the customers to improve the efficiency of the equipment, optimize design and operating conditions and enhance quality. For us, protection of customers data and process information is very critical.

FluiDimensions is founded formally in June 2016 by Dr. Vivek Vitankar, Ph.D, Chemical Engineering, ICT, Mumbai (formerly UDCT). Vivek has his Bachelors and Masters degree in Chemical Engineering from Laxmi Narayan Institute of Technology, (LIT) Nagpur, Maharashtra. Vivek did his PostDoctral Research at Chemical Engineering Department of Iowa State University, Iowa State, USA.

Vivek’s Ph.D and Postral research is in the area of Computational Fluid Dynamics for the Design of Multiphase Reactors (Bubble columns reactors).

After his Postdoctoral research, Vivek joined Aditya Birla Group Corporate R&D Center ( Aditya Birla Science and Technology Company Limited, (ABSTC) Mumbai) for 8 years. In this tenure, Vivek worked very closely for 8 years with Aditya Birla Group’s Manufacturing Business covering Cement, Cellulose and Fibers, Carbon Black, Chemicals, Copper, Aluminum and Fertilizers. Vivek worked very closely with the Manufacturing units and helped in improving reactor designs, yield, and quality. He could successfully reduce energy consumption and improve productivity and throughput for these manufacturing businesses. Vivek gathered domain knowledge of these wide variety of Manufacturing processes. He could get a very good insight of manufacturing need of implementable design solutions.

After having this strong foundation, Vivek worked for 4 years with UOP’s Honeywell India Technology Center, a Honeywell Company, Gurgaon, Haryana, India. Vivek led the Modeling Simulation Programs involving CFD, Kinetic Modeling and Molecular Modeling. Vivek was also responsible for Catalyst manufacturing technology Programs.

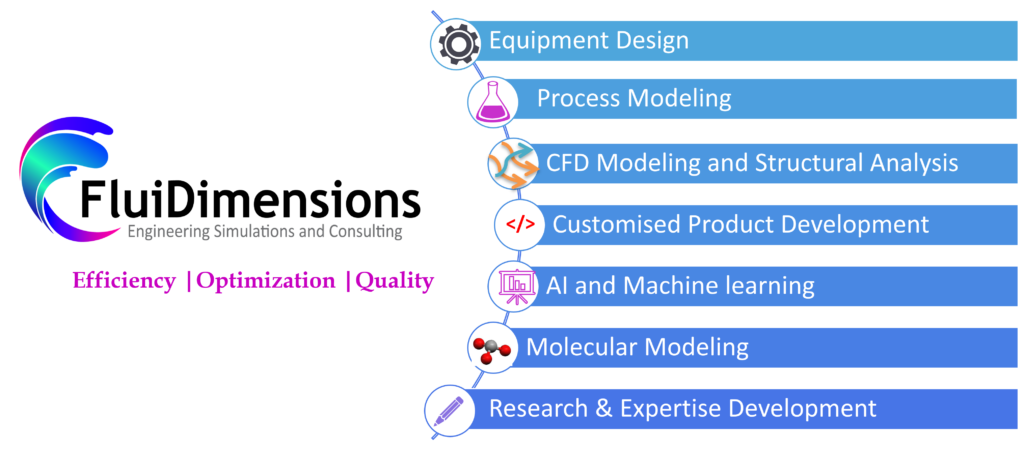

Engineering Simulation and Consulting Portfolio

FluiDimensions provides modeling and simulation services for Chemical and Process Industry. We design key chemical process equipments like stirred tank reactors, bubble columns, Cyclone separators, gas-liquid separators etc. We develop detailed process models using ASPEN Plus, DWSIM, Matlab etc.

We provide CFD modeling and Analysis of wide range of process equipments like stirred tank reactors, bubble columns, cyclone separators, heat exchangers, hot gas generators, spray driers, furnaces, gas-liquid separators, fluidized bed reactors, polymerization reactors, inline static mixers etc. we also perform structural analysis of the equipments to understand the structural strength, failure due to fluid -structural interactions. We model fluid-thermal-electrical coupled analysis.

FluiDimensions believes in solving industrial problems by working very closely with the customers to improve the efficiency of the equipment, optimize design and operating conditions and enhance quality. For us, protection of customers data and process information is very critical.